How an Extruder Machine Can Streamline Your Production Process

By:Admin

Established in 1995, {} has been a leading manufacturer of extruder machines and equipment for over two decades. The company specializes in providing high-quality and innovative solutions for the plastics, food, and feed industries. With a strong focus on research and development, {} has continuously strived to improve its products and processes, making it a trusted name in the industry.

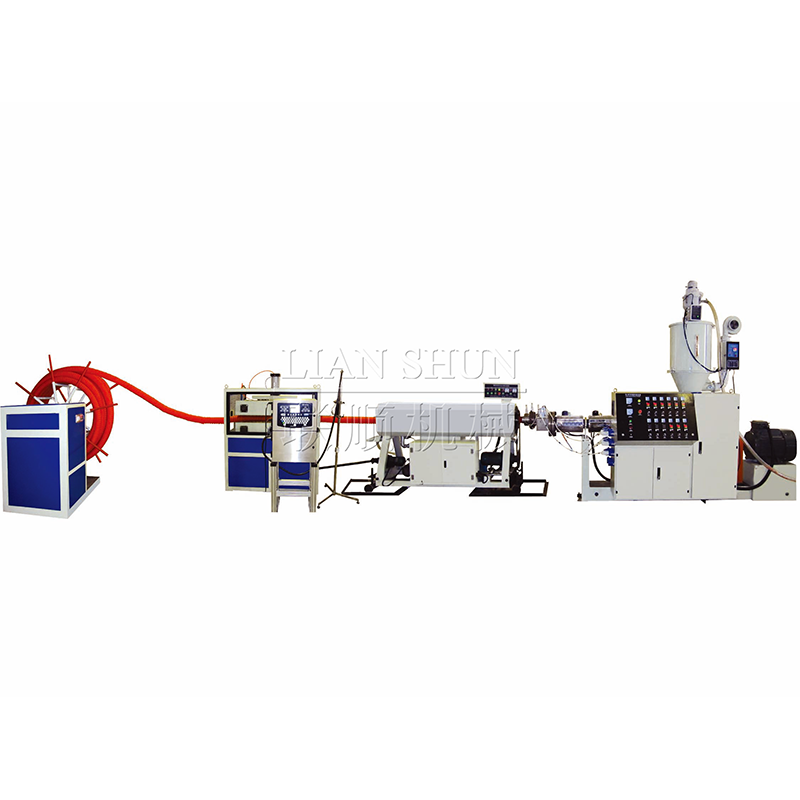

The extruder machine process is a manufacturing method that involves forcing raw material through a die to create a specific shape or form. This process is commonly used in the production of plastic products, such as pipes, tubes, and sheets, as well as in the food industry for creating snacks, breakfast cereals, and pet food. {}’s extruder machines are designed to meet the specific needs of its clients, offering custom solutions for different products and applications.

One of the key features of {}’s extruder machines is their versatility. The company’s machines can process a wide range of raw materials, including plastic resins, food ingredients, and animal feeds, allowing for a diverse range of end products. Furthermore, {}’s extruder machines are designed to be highly efficient, ensuring minimal waste and maximum productivity for its customers.

In addition to its high-quality extruder machines, {} also offers comprehensive support and services to its clients. The company’s team of experts provides technical assistance, installation and training services, and maintenance and spare parts support, ensuring that its clients’ operations run smoothly and efficiently. With a global network of sales and service partners, {} is able to provide timely and reliable support to its customers worldwide.

One of the key factors that sets {} apart from its competitors is its commitment to innovation. The company continuously invests in research and development to improve its products and processes, staying ahead of the curve in the rapidly evolving manufacturing industry. By embracing the latest technologies and industry trends, {} is able to offer cutting-edge solutions that meet the ever-changing needs of its clients.

Furthermore, {} places a strong emphasis on sustainability and environmental responsibility. The company’s extruder machines are designed to minimize energy consumption and waste generation, helping its clients reduce their environmental footprint. In addition, {} actively seeks to develop new technologies and processes that promote sustainability and contribute to a greener future for the manufacturing industry.

In conclusion, {} is a leading manufacturer of extruder machines and equipment, offering high-quality solutions for the plastics, food, and feed industries. With a strong focus on innovation, versatility, and sustainability, {} has established itself as a trusted partner for manufacturers worldwide. As the manufacturing industry continues to evolve, {} is poised to remain at the forefront, providing cutting-edge solutions for the ever-changing needs of its clients.

Company News & Blog

Understanding the Cost of PVC Pipe Machines

The demand for PVC pipe machines has been steadily increasing in the construction and manufacturing industries. PVC pipes are widely used for various applications, including water supply, irrigation, and drainage systems. As a result, the market for PVC pipe machines has seen significant growth in recent years. However, one of the major concerns for businesses looking to invest in PVC pipe machine is the cost.The cost of PVC pipe machines can vary significantly depending on various factors such as the machine's capacity, size, and technology used. In order to help businesses make informed decisions, it is important to consider both the initial cost of the machine and the long-term return on investment.One company that has been at the forefront of providing high-quality PVC pipe machines at competitive prices is {}. With over 20 years of experience in the industry, {} has established itself as a reliable and trusted supplier of PVC pipe machines.{} offers a wide range of PVC pipe machines, including extrusion lines, mixing machines, and auxiliary equipment. Their machines are known for their durability, efficiency, and high performance. In addition, {} provides customized solutions to meet the specific needs of their clients, ensuring that their machines are tailored to optimize productivity and minimize operational costs.When it comes to the cost of PVC pipe machines, {} strives to provide cost-effective solutions without compromising on quality. By leveraging their extensive industry knowledge and expertise, {} is able to offer competitive pricing on their machines, making them an attractive option for businesses looking to invest in PVC pipe manufacturing.One of the key elements that sets {} apart from their competitors is their commitment to delivering value to their customers. In addition to providing high-quality machines at competitive prices, {} also offers excellent after-sales support, including installation, training, and maintenance services. This ensures that their clients can maximize the efficiency of their PVC pipe machines and achieve the best possible return on their investment.By offering cost-effective solutions and comprehensive support, {} has earned a strong reputation in the industry, garnering the trust and loyalty of their clients. This has allowed {} to build long-lasting relationships with their customers, further solidifying their position as a leading supplier of PVC pipe machines.In conclusion, the cost of PVC pipe machines is an important consideration for businesses looking to invest in manufacturing equipment. With {}'s dedication to providing high-quality machines at competitive prices, businesses can confidently invest in PVC pipe machines knowing that they are getting excellent value for their money.As the demand for PVC pipes continues to grow, businesses can rely on {} to provide cost-effective solutions that meet their production needs. With their commitment to quality, affordability, and customer satisfaction, {} is well-positioned to remain a trusted partner for businesses in the PVC pipe manufacturing industry.

Understanding the Cost of Extruder Machines: What You Need to Know

Cost Of Extruder MachineThe cost of an extruder machine is a crucial consideration for companies in the manufacturing and processing industries. Extruder machines are utilized in various industries for the production of a wide range of products including food items, plastic materials, rubber, and more. The cost of an extruder machine can vary depending on several factors such as size, capacity, features, and brand. One of the leading manufacturers of extruder machines is [Company Name]. With over [X] years of experience in the industry, [Company Name] has a reputation for producing high-quality and innovative extruder machines that cater to the diverse needs of their customers. As a company, [Company Name] is committed to providing their customers with state-of-the-art extruder machines that are not only efficient but also cost-effective.When it comes to the cost of extruder machines, it is important to consider the specific requirements of the manufacturing or processing operations. The cost of an extruder machine can range from a few thousand dollars to several hundred thousand dollars. The size and capacity of the machine play a significant role in determining the cost, with larger and more powerful machines typically being more expensive.In addition to size and capacity, the features and capabilities of the extruder machine can also impact its cost. Extruder machines come with a variety of features such as advanced control systems, multiple extrusion capabilities, automated functions, and more. These features can add to the overall cost of the machine but are often essential for companies looking to optimize their production processes.Furthermore, the brand of the extruder machine can also influence its cost. While there are numerous manufacturers of extruder machines in the market, established and reputable brands like [Company Name] may come with a higher price tag due to their quality, reliability, and after-sales support. However, investing in a well-known brand can also provide companies with the assurance of superior performance and longevity.It is also important to note that the cost of an extruder machine is not limited to its initial purchase price. Companies must consider additional expenses such as installation, training, maintenance, and ongoing operational costs. These factors should be carefully evaluated to ensure that the total cost of ownership of the extruder machine aligns with the company's budget and operational requirements.In conclusion, the cost of an extruder machine can vary based on factors such as size, capacity, features, and brand. As a leading manufacturer in the industry, [Company Name] is dedicated to providing their customers with cost-effective extruder machines that deliver exceptional performance and value. By understanding their specific production needs and carefully evaluating the various cost considerations, companies can make informed decisions when investing in an extruder machine that will contribute to their success and growth in the industry.

Efficient Plastic Bottle Shredder: The Ideal Solution for Recycling Needs

Plastic Bottle Shredder: Revolutionizing Recycling EffortsIn an age where environmental sustainability is of paramount importance, finding innovative solutions to tackle the ever-increasing plastic waste has become crucial. One company at the forefront of this environmental revolution is {Company Name}, with their cutting-edge Plastic Bottle Shredder. This groundbreaking device is revolutionizing recycling efforts, providing a sustainable solution to the global plastic waste crisis.{Company Name} is a renowned leader in the recycling industry, continuously striving to develop innovative technologies that promote sustainability. With a focus on reducing plastic pollution and creating a circular economy, their Plastic Bottle Shredder has emerged as a game-changer.The Plastic Bottle Shredder is a robust machine designed specifically for processing plastic bottles. Through its efficient shredding mechanism, it can effectively reduce plastic bottles to small fragments, making them easier to handle and recycle. This process essentially transforms plastic waste into a valuable resource.Designed with durability in mind, the Plastic Bottle Shredder is built to withstand the challenges of continuous operation. Its reliable performance ensures maximum productivity, allowing recycling facilities to process large quantities of plastic bottles efficiently. Moreover, the shredder operates at low noise levels, minimizing disruptions and allowing for a more comfortable work environment.One of the key features of the Plastic Bottle Shredder is its versatility. It can handle various types of plastic bottles, including PET bottles, HDPE bottles, and PVC bottles, among others. This flexibility makes it an ideal choice for recycling centers and waste management facilities that deal with a wide range of plastic waste.The shredder's advanced technology enables a high level of safety and efficiency. Equipped with intelligent sensors and control systems, it ensures smooth operation and prevents overloading or jamming. Additionally, the integrated dust extraction system effectively captures airborne particles that are released during the shredding process, enhancing overall workplace hygiene.{Company Name}'s commitment to sustainability extends beyond the design of the Plastic Bottle Shredder. They provide comprehensive support to clients, including installation, training, and maintenance services. This ensures optimal performance and longevity of the machines, helping recycling facilities maximize their impact on reducing plastic waste.With multiple successful installations worldwide, the Plastic Bottle Shredder has garnered significant recognition for its outstanding performance. Recycling facilities equipped with this innovative technology have experienced increased productivity, reduced operational costs, and enhanced environmental sustainability. Through the efficient shredding of plastic bottles, they contribute to the creation of a circular economy, where waste is minimized, and resources are reused.{Company Name} continues to lead the charge in revolutionizing recycling efforts globally. They remain committed to research and development, constantly seeking new ways to improve and optimize their plastic waste management solutions. By collaborating with industry partners, environmental organizations, and government agencies, they strive to create a more sustainable future.In conclusion, the Plastic Bottle Shredder from {Company Name} is a groundbreaking device that is transforming recycling efforts. With its efficient and versatile design, it enables recycling facilities to process large quantities of plastic bottles, contributing to the reduction of plastic waste and the creation of a circular economy. With their commitment to sustainability and continuous improvement, {Company Name} is leading the charge to combat plastic pollution and create a greener future for our planet.

Industrial Recycling Shredder: A Complete Guide

Recycling Shredder: A Solution for Sustainable Waste ManagementIn today's world, the issue of waste management has become more critical than ever. With the global population increasing and the amount of waste produced growing at an alarming rate, it has become essential to find sustainable solutions for managing and recycling waste. One company that has been leading the way in this endeavor is {Company Name}, which has developed an innovative recycling shredder that is revolutionizing the recycling industry.{Company Name} is a leading provider of environmentally friendly waste management solutions, with a strong commitment to sustainability and environmental responsibility. The company's mission is to provide efficient and effective waste management solutions that minimize environmental impact and make a positive contribution to the planet. With a focus on developing cutting-edge technology and sustainable processes, {Company Name} has become a trusted name in the recycling industry.One of the company's most significant achievements is the development of a state-of-the-art recycling shredder that sets a new standard for efficiency and performance in waste management. This cutting-edge machine is designed to process a wide range of materials, including plastic, paper, cardboard, and electronic waste, making it a versatile and cost-effective solution for recycling facilities and waste management companies.The recycling shredder is equipped with advanced shredding technology that allows it to process large volumes of material quickly and efficiently. Its high-speed motor and precision cutting blades ensure that it can handle even the toughest and most challenging materials with ease, making it a valuable asset for any recycling operation. Furthermore, the shredder is designed to minimize energy consumption and reduce operating costs, making it a sustainable and environmentally friendly solution for waste management.{Company Name} has also invested in research and development to continuously improve the performance and capabilities of its recycling shredder. The company's team of engineers and experts are dedicated to enhancing the machine's efficiency, reliability, and durability, ensuring that it remains at the forefront of waste management technology. As a result, the recycling shredder has become a game-changer for recycling facilities, allowing them to increase their processing capacity, reduce waste volumes, and improve their overall operational efficiency.Moreover, the recycling shredder's user-friendly design and intuitive controls make it easy to operate and maintain, providing operators with a hassle-free and seamless experience. Its robust construction and high-quality components ensure that it can withstand the demanding conditions of waste processing facilities, minimizing downtime and maximizing productivity. Additionally, the shredder is designed to meet stringent safety standards, providing operators with peace of mind and a secure working environment.{Company Name} is dedicated to providing comprehensive support and service for its recycling shredder, ensuring that customers receive ongoing assistance and technical expertise. The company's team of professionals is committed to helping clients integrate the shredder into their operations, providing training, maintenance, and troubleshooting services as needed. With a focus on customer satisfaction and long-term partnerships, {Company Name} aims to deliver value and excellence in every aspect of its business.The recycling shredder from {Company Name} is a testament to the company's commitment to innovation, sustainability, and environmental stewardship. By providing a reliable and efficient solution for waste management, the company is playing a crucial role in building a more sustainable and circular economy. With its cutting-edge technology and dedication to excellence, {Company Name} is leading the way toward a greener and more sustainable future for waste management.In conclusion, the recycling shredder from {Company Name} is a game-changing solution for sustainable waste management, offering unmatched efficiency, performance, and reliability. As the demand for environmentally friendly waste solutions continues to grow, {Company Name} is well-positioned to make a significant and positive impact on the recycling industry. With its ongoing commitment to innovation and sustainability, the company is set to remain a leader in the field of waste management for years to come.

Affordable Plastic Grinder Price: Find Competitive Deals Online

In the ever-evolving world of recycling and waste management, there is a growing need for efficient plastic grinding machines. One company that has been making waves in this industry is {company name}. Known for their innovative and high-quality equipment, they have recently launched a new plastic grinder that has been creating quite a buzz in the market.The {company name} has been a leading player in the field of recycling and waste management equipment for over a decade. With a strong focus on research and development, they have continuously strived to bring cutting-edge solutions to their customers. Their commitment to quality and customer satisfaction has earned them a strong reputation in the industry.The latest addition to their product line is the new plastic grinder, designed to meet the growing demand for efficient and reliable grinding machines. The grinder comes with a range of features that set it apart from its competitors. It is equipped with a powerful motor and sharp blades that ensure efficient grinding of plastic waste. The machine is also designed for easy operation and maintenance, making it an ideal choice for recycling facilities and waste management companies.One of the key highlights of this new plastic grinder is its competitive price. {company name} has managed to offer this high-quality machine at a price that is significantly lower than its counterparts in the market. This has made the grinder extremely attractive to businesses looking to invest in cost-effective recycling equipment without compromising on performance and quality.The {company name} plastic grinder has already garnered attention from a number of businesses in the recycling industry. Many have expressed their interest in the machine, citing its affordable price and impressive features as major selling points. Some have even gone as far as to pre-order the grinder, eager to get their hands on this new and promising equipment.In addition to the quality and affordability of their products, {company name} is also known for their excellent customer service. They have a team of knowledgeable and skilled professionals who are dedicated to providing support and assistance to their customers. This commitment to customer satisfaction has helped them build strong and lasting relationships with businesses in the recycling and waste management sector.With the launch of their new plastic grinder, {company name} has once again demonstrated their dedication to providing innovative and cost-effective solutions to their customers. The grinder is expected to make a significant impact in the recycling industry, helping businesses to improve their waste management processes and reduce their environmental footprint.In conclusion, the launch of {company name}'s new plastic grinder is a testament to their continuous efforts to push the boundaries of innovation in the recycling and waste management industry. The machine's high-quality performance, competitive price, and the company's strong reputation make it a compelling choice for businesses looking to invest in efficient plastic grinding equipment. As the demand for sustainable waste management solutions continues to grow, {company name} is well-positioned to lead the way with their range of cutting-edge products.

Industry's Latest Advancement: Unveiling the Impressive Co Extruder Technology

[Company Name] Introduces Revolutionary Co Extruder Technology[City, Date] - [Company Name], a leading international technology company, is proud to announce the launch of their latest innovation in the field of extrusion technology - the Co Extruder. This groundbreaking technology promises to revolutionize the manufacturing industry by providing a more efficient and cost-effective solution for extrusion processes.Extrusion is a commonly used manufacturing process in industries such as plastic, food, and pharmaceuticals. It involves pushing a material through a die to create a specific shape or form. Traditionally, extrusion processes have been limited by the use of single extruders. However, the introduction of the Co Extruder by [Company Name] eliminates this limitation and opens up new possibilities for manufacturers.The Co Extruder is a state-of-the-art machine that combines the power of multiple extruders into a single system. This innovative design allows for the simultaneous extrusion of multiple materials, resulting in enhanced manufacturing capabilities and increased productivity. With the ability to combine materials of different colors, textures, and properties, manufacturers can now create products with advanced functionalities and unique designs.One of the key advantages of the Co Extruder is its flexibility. Unlike traditional extruders, which are limited to a single material, the Co Extruder offers the freedom to experiment with different combinations of materials, providing endless possibilities for product development. This versatility opens up opportunities for manufacturers to create customized solutions tailored to their clients' specific needs.In addition to its flexibility, the Co Extruder also offers significant cost savings. By combining multiple extruders into a single system, manufacturers can reduce both the initial investment and ongoing operational costs associated with extrusion processes. This makes the technology highly attractive for small and medium-sized enterprises looking to streamline their manufacturing processes without compromising on quality.Furthermore, the Co Extruder boasts advanced automation features that enhance efficiency and reduce the risk of human error. With precise control over temperature, pressure, and speed, manufacturers can achieve consistent and high-quality extrusion results, ensuring product integrity and customer satisfaction.[Company Name] has a long-standing reputation for delivering innovative solutions to the manufacturing industry. By introducing the Co Extruder, the company reaffirms its commitment to pushing boundaries and driving technological advancements. The Co Extruder is the result of extensive research and development efforts by a team of experts dedicated to finding solutions that address the evolving needs of the industry."We are thrilled to introduce the Co Extruder to the market," says [Company Name]'s CEO. "This technology represents a significant milestone in the extrusion industry, offering manufacturers unprecedented flexibility, efficiency, and cost savings. We believe that the Co Extruder will revolutionize the way products are manufactured and open up new opportunities for our clients to differentiate themselves in the market."The Co Extruder is now available for purchase worldwide, and [Company Name] is actively seeking partnerships with manufacturers looking to leverage this cutting-edge technology. With its wide range of applications across various industries, the Co Extruder is set to transform the manufacturing landscape and establish [Company Name] as a leader in the field.About [Company Name]:[Company Name] is a global technology company specializing in innovative solutions for the manufacturing industry. With a focus on research and development, the company has a track record of introducing groundbreaking technologies that drive efficiency, productivity, and sustainability. With a strong commitment to customer satisfaction, [Company Name] strives to deliver exceptional products and services that exceed expectations.

High-Quality Plastic Shredder for Effective Recycling

ABC Company, a leading manufacturer of industrial equipment, has recently unveiled its latest product, the plastic shredder for recycling. This new addition to their lineup is designed to meet the increasing demand for sustainable solutions in the recycling industry.The plastic shredder for recycling is a powerful machine that is capable of shredding a wide range of plastic materials, including PET bottles, HDPE containers, and PVC pipes. It is equipped with high-quality blades that are able to efficiently break down the plastic waste into smaller pieces, making it easier to process and recycle.One of the key features of the plastic shredder is its robust construction, which is designed to withstand the rigorous demands of industrial recycling operations. The machine is built with durable materials and components, ensuring that it can handle heavy-duty shredding tasks with ease.In addition, the plastic shredder is also equipped with advanced safety features to protect workers and prevent accidents in the workplace. It comes with safety guards and emergency stop buttons, as well as a built-in overload protection system to prevent damage to the machine.The plastic shredder for recycling is also designed with convenience in mind. It features a user-friendly control panel that allows operators to easily adjust the shredding parameters and monitor the machine's performance. Additionally, the machine is equipped with a large hopper and a powerful conveyor belt, which streamline the feeding process and improve overall efficiency.ABC Company has a long history of providing high-quality industrial equipment to various industries, and the plastic shredder for recycling is a testament to their commitment to innovation and sustainability. With this new product, they aim to help businesses and organizations effectively manage their plastic waste and contribute to a cleaner, greener environment.In a statement, a spokesperson for ABC Company expressed their excitement about the launch of the plastic shredder for recycling. They stated, "We are proud to introduce this cutting-edge machine to the market. As the global focus on environmental sustainability continues to grow, we believe that our plastic shredder will play a crucial role in helping businesses and recycling facilities manage their plastic waste more effectively."The plastic shredder for recycling is expected to make a significant impact in the recycling industry, offering a viable solution for processing plastic waste and reducing the burden on landfills. With its robust construction, advanced safety features, and user-friendly design, this machine is set to revolutionize the way plastic waste is managed and recycled.ABC Company is confident that their plastic shredder for recycling will be well-received by businesses and organizations seeking sustainable solutions for their plastic waste. They are committed to providing comprehensive support and service for their customers, ensuring that the plastic shredder delivers exceptional performance and reliability for years to come.

Twin Screw Extrusion Line Offers Advanced Technology for Manufacturing

High-Quality Lab Twin Screw Extrusion Line Launched by Leading Machinery Company[Company Name], a leading manufacturer of industrial machinery and equipment, has recently launched its latest innovation in the field of extrusion technology - the high-quality Lab Twin Screw Extrusion Line. This state-of-the-art extrusion line is designed to meet the ever-growing demand for precision and efficiency in the production of various plastic, rubber, and food products.The Lab Twin Screw Extrusion Line is a versatile and reliable solution that caters to the needs of research and development laboratories, small-scale production facilities, and educational institutions. With its compact design and superior performance, this extrusion line is ideal for producing small batches of materials for testing and experimentation purposes.The key features of the Lab Twin Screw Extrusion Line include:- High torque, co-rotating twin-screw extruder- Precise temperature and speed control- Modular configuration for flexibility and scalability- Easy operation and maintenanceThe extrusion line is capable of processing a wide range of materials, including thermoplastics, elastomers, and food ingredients, making it suitable for a variety of applications such as compounding, mixing, granulation, and extrusion.In addition to its advanced technical capabilities, the Lab Twin Screw Extrusion Line is designed with a focus on user-friendly operation and safety. The intuitive control system allows for easy adjustment of process parameters, while built-in safety features ensure reliable and trouble-free operation.As a leading supplier of extrusion machinery, [Company Name] is committed to delivering high-quality solutions that meet the specific needs of its customers. The Lab Twin Screw Extrusion Line is the result of extensive research and development efforts, aimed at providing a reliable and cost-effective solution for small-scale production and testing.With this latest addition to its product portfolio, [Company Name] strengthens its position as a trusted provider of advanced extrusion technology. The company's expertise in the design and manufacturing of extrusion equipment is backed by years of experience and a proven track record of delivering innovative solutions to the industry."We are excited to introduce the Lab Twin Screw Extrusion Line to the market," said a spokesperson for [Company Name]. "This extrusion line represents a significant advancement in our product offering, and we are confident that it will provide valuable benefits to our customers in terms of efficiency, performance, and flexibility."The launch of the Lab Twin Screw Extrusion Line underscores [Company Name]'s commitment to driving innovation and meeting the evolving needs of the extrusion industry. The company's dedication to quality, reliability, and customer satisfaction is exemplified in its latest offering, which is poised to set new standards for small-scale extrusion applications.As the demand for precision and versatility in extrusion processes continues to grow, the Lab Twin Screw Extrusion Line is well-positioned to meet the needs of research and development facilities, educational institutions, and small-scale production operations. With its superior performance, user-friendly design, and reliable operation, this extrusion line is set to make a significant impact in the industry.In conclusion, the launch of the high-quality Lab Twin Screw Extrusion Line by [Company Name] marks a significant milestone in the field of extrusion technology. With its advanced features and versatile capabilities, this extrusion line is set to provide valuable benefits to its users in terms of precision, efficiency, and reliability. As a leading supplier of extrusion machinery, [Company Name] continues to demonstrate its commitment to delivering innovative solutions that meet the evolving needs of the industry.

Efficient Plastic Pelletizer for High-Quality Production

Plastic manufacturing companies around the world are constantly looking for innovative solutions to improve their production processes and reduce waste. One company that has been at the forefront of developing cutting-edge solutions for the plastics industry is {}.{} is a leading manufacturer of plastic processing machinery and equipment, specializing in the design and production of plastic pelletizers. The company has a strong reputation for its high-quality products and innovative technologies, and it has been dedicated to helping plastic manufacturers streamline their production processes and minimize waste generation.One of {}'s most recent innovations is the development of a state-of-the-art plastic pelletizer that is revolutionizing the way plastic manufacturers process and recycle their materials. The new pelletizer is designed to efficiently and effectively convert plastic waste into high-quality pellets that can be used in a wide range of applications, including the manufacturing of new plastic products.The plastic pelletizer is equipped with advanced features and technologies that set it apart from traditional pelletizing equipment. It is designed to handle a wide variety of plastic materials, including both virgin and recycled plastics, and it can produce pellets of consistent size and quality. This level of precision and consistency is crucial for manufacturers who rely on high-quality pellets to produce their products.In addition to its advanced capabilities, the plastic pelletizer also offers enhanced energy efficiency and production capacity. Thanks to its innovative design and engineering, the pelletizer is able to process larger quantities of plastic materials in a shorter amount of time, reducing the overall energy consumption and labor costs associated with pelletizing operations.Furthermore, the plastic pelletizer is designed with a focus on sustainability and environmental responsibility. By enabling manufacturers to efficiently recycle their plastic waste and transform it into reusable pellets, the pelletizer plays a key role in reducing the environmental impact of plastic production and consumption. This aligns with {}'s commitment to developing eco-friendly solutions for the plastics industry.Another key advantage of the plastic pelletizer is its versatility. It can be customized to meet the specific needs and requirements of different plastic manufacturers, allowing them to optimize the pelletizing process for their unique production workflows. This level of flexibility is invaluable for companies that produce a wide range of plastic products and need a pelletizer that can adapt to their changing needs.The plastic pelletizer is already generating significant interest and excitement within the plastics industry, with many manufacturers recognizing the potential benefits it offers for their operations. By investing in this innovative technology, companies can improve their production processes, reduce waste, and contribute to a more sustainable and circular economy.As {} continues to lead the way in developing advanced solutions for the plastics industry, the company remains dedicated to supporting manufacturers in their efforts to improve efficiency, reduce environmental impact, and achieve their production goals. With its new plastic pelletizer, {} is poised to make a significant impact on the way plastic materials are processed and recycled, paving the way for a more sustainable and resource-efficient future for the plastics industry.

Hdpe Pipe Production Line: Key Insights into High-Density Polyethylene Pipe Manufacturing

Title: Innovative HDPE Pipe Production Line Revolutionizes Manufacturing ProcessIntroduction:In an era of rapidly advancing technology where efficiency and sustainability are paramount, the launch of an innovative HDPE Pipe Production Line by a pioneering industry player has garnered significant attention within the manufacturing sector. With its advanced features and cutting-edge technology, this revolutionary production line is set to redefine the HDPE pipe manufacturing process and enhance overall productivity while maintaining a strong focus on environmental sustainability.The HDPE Pipe Production Line:The HDPE Pipe Production Line, developed by a leading manufacturing company, incorporates state-of-the-art technology to deliver an efficient and seamless production process. This modern production line allows for the rapid and continuous extrusion of high-density polyethylene (HDPE) pipes, making it ideal for meeting the growing demands of various industries.One of the key features of this production line is its intelligent control system. By leveraging innovative algorithms and automation, the system ensures precise control over pipe dimensions, thickness, and quality. Such accuracy significantly reduces material waste and ensures consistent product quality, reinforcing the company's commitment to sustainability.Furthermore, the HDPE Pipe Production Line incorporates advanced cooling techniques to enhance the cooling process and expedite pipe formation. This feature increases production speed while maintaining the required product specifications, resulting in improved productivity and reduced production costs. The ability to produce a wide range of pipe sizes further adds to the versatility and effectiveness of this state-of-the-art production line.Company Background:{} (company name), the mastermind behind this groundbreaking HDPE Pipe Production Line, is a renowned manufacturing company with a rich history of innovation and expertise. Having catered to the evolving needs of various industries for several decades, the company has established itself as a leader in the field.With a strong focus on research and development, {} has continually introduced cutting-edge technologies to optimize production processes and provide sustainable solutions for its clients. Thanks to the company's unwavering commitment to quality, reliability, and customer satisfaction, it has gained a global reputation and positioned itself as an industry pioneer.Environmental Sustainability:Recognizing the pressing need for sustainable manufacturing practices, {} has embedded environmental consciousness into the heart of its operations. The HDPE Pipe Production Line addresses this concern by utilizing HDPE, a recyclable material renowned for its durability and resistance to corrosion.By producing HDPE pipes efficiently and with minimal waste, the production line contributes to a significant reduction in carbon footprint. Additionally, with the ability to recycle and repurpose HDPE pipes at the end of their lifecycle, this solution aligns with the principles of the circular economy, fostering a more sustainable and eco-friendly manufacturing approach.Market Impact:The introduction of the HDPE Pipe Production Line by {} has already caused ripples in the market. The advanced features and efficiency of this production line promise to revolutionize the manufacturing process, significantly increasing productivity and reducing overall costs for companies operating in various industrial sectors.Furthermore, the heightened environmental consciousness inherent in the production line's design appeals to businesses seeking sustainable solutions. As regulations and industry standards are increasingly geared towards eco-friendly practices, the HDPE Pipe Production Line positions {} as a forerunner in meeting the changing demands of the market.Conclusion:With the unveiling of its innovative HDPE Pipe Production Line, {} has reaffirmed its commitment to transformative solutions that revolutionize manufacturing processes. By leveraging cutting-edge technology, the company has created a production line that optimizes efficiency, reduces waste, and promotes sustainability – all while meeting the growing demands of the industrial sector. As {} continues to spearhead advancements in the industry, its contribution to the manufacturing sector's progression remains unparalleled.