Efficient Plastic Bottle Shredder: The Ideal Solution for Recycling Needs

Plastic Bottle Shredder: Revolutionizing Recycling EffortsIn an age where environmental sustainability is of paramount importance, finding innovative solutions to tackle the ever-increasing plastic waste has become crucial. One company at the forefront of this environmental revolution is {Company Name}, with their cutting-edge Plastic Bottle Shredder. This groundbreaking device is revolutionizing recycling efforts, providing a sustainable solution to the global plastic waste crisis.{Company Name} is a renowned leader in the recycling industry, continuously striving to develop innovative technologies that promote sustainability. With a focus on reducing plastic pollution and creating a circular economy, their Plastic Bottle Shredder has emerged as a game-changer.The Plastic Bottle Shredder is a robust machine designed specifically for processing plastic bottles. Through its efficient shredding mechanism, it can effectively reduce plastic bottles to small fragments, making them easier to handle and recycle. This process essentially transforms plastic waste into a valuable resource.Designed with durability in mind, the Plastic Bottle Shredder is built to withstand the challenges of continuous operation. Its reliable performance ensures maximum productivity, allowing recycling facilities to process large quantities of plastic bottles efficiently. Moreover, the shredder operates at low noise levels, minimizing disruptions and allowing for a more comfortable work environment.One of the key features of the Plastic Bottle Shredder is its versatility. It can handle various types of plastic bottles, including PET bottles, HDPE bottles, and PVC bottles, among others. This flexibility makes it an ideal choice for recycling centers and waste management facilities that deal with a wide range of plastic waste.The shredder's advanced technology enables a high level of safety and efficiency. Equipped with intelligent sensors and control systems, it ensures smooth operation and prevents overloading or jamming. Additionally, the integrated dust extraction system effectively captures airborne particles that are released during the shredding process, enhancing overall workplace hygiene.{Company Name}'s commitment to sustainability extends beyond the design of the Plastic Bottle Shredder. They provide comprehensive support to clients, including installation, training, and maintenance services. This ensures optimal performance and longevity of the machines, helping recycling facilities maximize their impact on reducing plastic waste.With multiple successful installations worldwide, the Plastic Bottle Shredder has garnered significant recognition for its outstanding performance. Recycling facilities equipped with this innovative technology have experienced increased productivity, reduced operational costs, and enhanced environmental sustainability. Through the efficient shredding of plastic bottles, they contribute to the creation of a circular economy, where waste is minimized, and resources are reused.{Company Name} continues to lead the charge in revolutionizing recycling efforts globally. They remain committed to research and development, constantly seeking new ways to improve and optimize their plastic waste management solutions. By collaborating with industry partners, environmental organizations, and government agencies, they strive to create a more sustainable future.In conclusion, the Plastic Bottle Shredder from {Company Name} is a groundbreaking device that is transforming recycling efforts. With its efficient and versatile design, it enables recycling facilities to process large quantities of plastic bottles, contributing to the reduction of plastic waste and the creation of a circular economy. With their commitment to sustainability and continuous improvement, {Company Name} is leading the charge to combat plastic pollution and create a greener future for our planet.

Read More

Profile Extrusion Machine for WPC: News Report Highlights the Latest Developments

WPC Profile Extrusion Machine Drives Innovation in the Construction Industry[City, Date] - In a bid to revolutionize the construction industry, a leading manufacturer of extrusion machinery has introduced a state-of-the-art WPC Profile Extrusion Machine. This cutting-edge technology is set to transform the way composite materials are used in the building and construction sector, bringing numerous advantages in terms of durability, sustainability, and design possibilities.Wood Plastic Composites, commonly referred to as WPC, are composite materials made from a combination of wood fibers or flour and thermoplastics. These materials offer exceptional properties such as resistance to moisture, rot, and insects, making them an ideal alternative to traditional wooden profiles used in construction.The newly launched WPC Profile Extrusion Machine is designed to streamline the manufacturing process of WPC profiles. Equipped with advanced features and cutting-edge technology, this machine offers precise control over the extrusion parameters, ensuring consistent quality and dimensional accuracy of the produced profiles.One of the key advantages of using WPC profiles in construction is their increased durability compared to traditional materials. The combination of wood fibers and thermoplastics lends these profiles enhanced strength and resistance to weathering, ultimately extending their lifespan. Additionally, WPC is highly resistant to moisture, eliminating issues such as warping, rotting, or splintering commonly associated with wooden profiles.Another significant benefit of WPC profiles is their sustainable nature. By utilizing wood fibers derived from recycled or sustainably managed sources, manufacturers can significantly reduce their carbon footprint while still delivering high-performance construction materials. This eco-friendly aspect of WPC aligns with global initiatives towards more sustainable building practices.The versatility of WPC profiles is yet another reason behind their increasing popularity in the construction industry. These profiles can be manufactured in a wide range of shapes, sizes, and colors, enabling architects, designers, and builders to experiment and create unique structures. Whether it's decking, fencing, cladding, or interior applications, WPC profiles offer endless design possibilities, allowing for both functional and aesthetically pleasing solutions.In addition to the advancements in the manufacturing process, the company behind this innovative WPC Profile Extrusion Machine is renowned for its commitment to quality and customer satisfaction. With years of experience in the extrusion machinery industry, their team of experts ensures the flawless operation and longevity of their products.The commitment to customer satisfaction is reflected in the company's comprehensive after-sales support. This includes technical assistance, training, and regular maintenance to optimize the performance of the WPC Profile Extrusion Machine and ensure its longevity.The introduction of the WPC Profile Extrusion Machine comes at a time when the construction industry is seeking sustainable and innovative materials. With its durability, sustainability, and design possibilities, WPC profiles are increasingly being embraced as a viable alternative to traditional building materials.As the construction industry continues to evolve, demand for WPC profiles is anticipated to rise. The WPC Profile Extrusion Machine is set to play a vital role in meeting this demand, driving innovation and enabling builders to construct structures that are not only visually appealing but also durable and eco-friendly.In conclusion, the introduction of the WPC Profile Extrusion Machine marks a significant milestone in the construction industry. By leveraging the advantages offered by WPC profiles, builders can create structures that combine sustainability, durability, and aesthetic appeal. With the commitment to quality and customer satisfaction demonstrated by the manufacturer, the future looks promising for the adoption of WPC profiles in construction projects worldwide.

Read More

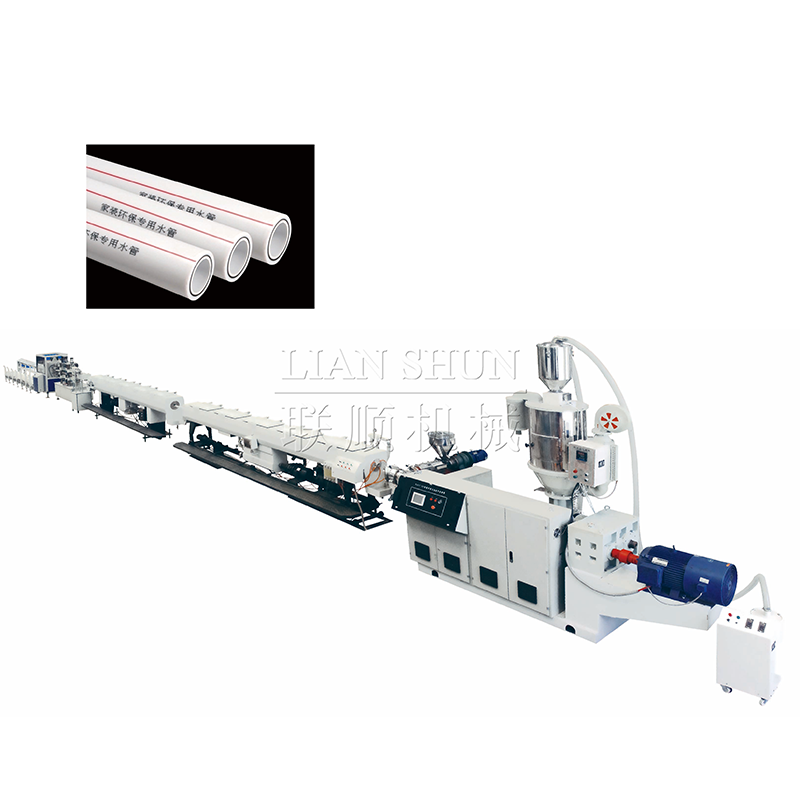

PVC Pipe Manufacturing Machine: An insight into the production process

PVC Pipe Manufacturing Machine Revolutionizes the IndustryThe global demand for PVC pipes is steadily increasing with the growth of construction activities, urbanization, and agricultural development. As a result, manufacturers are constantly seeking ways to increase their production capacity and efficiency. This quest for innovation has led to the development of the state-of-the-art PVC Pipe Manufacturing Machine, which is set to revolutionize the industry.The newly launched PVC Pipe Manufacturing Machine, developed by a prominent industry player (brand name removed), boasts cutting-edge technology and advanced features. This machine has been designed to streamline the entire production process, from raw material handling to the final product. It promises to significantly reduce the labor-intensive tasks associated with traditional manufacturing methods, resulting in increased productivity and cost-effectiveness for manufacturers.One of the key features of this PVC Pipe Manufacturing Machine is its automated operation. Equipped with modern control systems, it can perform complex tasks with minimal human intervention. This not only eliminates errors and inconsistencies but also enhances overall production efficiency. The machine ensures accurate and precise pipe dimensions, allowing manufacturers to deliver high-quality products consistently.Efficiency is further enhanced by the machine's capability to handle a wide range of pipe sizes. With customizable settings, manufacturers can produce pipes of various diameters and lengths as per their specific requirements. This flexibility enables them to cater to a broader market, providing a competitive edge in the industry.The advanced technology integrated into the PVC Pipe Manufacturing Machine also ensures energy optimization. With energy costs being a significant concern for manufacturers, this machine comes as a breath of fresh air. It minimizes power consumption by utilizing energy-efficient motors and advanced heating and cooling systems. This not only reduces operating costs but also contributes to sustainability efforts by lowering the carbon footprint of manufacturing processes.Moreover, the machine's user-friendly interface offers ease of operation and monitoring for operators. The control panel displays real-time data on production speed, error detection, and maintenance requirements, allowing operators to make informed decisions promptly. The automated quality control system constantly monitors the production process, identifying and rectifying any faults in real-time. This results in improved product consistency and reduced waste.Additionally, the PVC Pipe Manufacturing Machine's durability and reliability ensure long-term productivity. Constructed with high-quality materials and components, it can withstand the demands of continuous operation. This significantly reduces machine downtime and maintenance costs, translating into enhanced profitability for manufacturers.As a market leader in the manufacturing industry, the company behind this revolutionary machine is committed to providing exceptional customer support. They offer comprehensive training for machine operators to ensure efficient utilization and maximize its potential. Additionally, their after-sales service includes prompt technical assistance, spare parts availability, and regular maintenance. This commitment to customer satisfaction sets them apart from their competitors.Overall, the introduction of the PVC Pipe Manufacturing Machine marks a significant breakthrough in the industry. Its advanced features, energy efficiency, flexibility, and reliability are set to redefine the manufacturing process for PVC pipes. With its ability to meet the growing demands of the market, this innovative machine will undoubtedly revolutionize the global PVC pipe industry and drive greater growth and success for manufacturers worldwide.

Read More

Enhance Your Pipe Production with a Cutting-Edge Extrusion Machine

Title: Revolutionizing Pipe Manufacturing through Innovative Extrusion TechnologyIntroduction:In an era of rapid industrialization and urbanization, the demand for high-quality pipes for various applications has been escalating. To cater to this growing need, the pioneering engineers at a leading manufacturing company have developed an advanced Pipe Extrusion Machine capable of revolutionizing the pipe manufacturing industry. By leveraging cutting-edge technology and adhering to stringent quality standards, this innovation promises to deliver durable and efficient pipes for a wide range of industrial, commercial, and residential applications.Innovative Features:The advanced Pipe Extrusion Machine eliminates the traditional bottlenecks and challenges associated with pipe production. With an optimal combination of precision engineering and automation, this state-of-the-art machine can seamlessly manufacture pipes with exceptional precision, consistency, and strength. Its key features include:Advanced Extrusion Technology: The machine harnesses advanced extrusion technology, which ensures a smooth and continuous flow of raw materials, resulting in pipes with uniform thickness and excellent surface finish. The extrusion process guarantees consistent quality across the entire length of the pipe, enabling manufacturers to deliver high-performance products.Integrated Control System: Equipped with an intelligent and intuitive control system, the Pipe Extrusion Machine enables seamless adjustments throughout the manufacturing process. Manufacturers can easily regulate parameters such as temperature, pressure, and speed, ensuring total control over the pipe's physical attributes to meet specific application requirements.Versatility: The machine can produce pipes of various diameters and lengths, catering to a wide range of applications such as water supply, drainage, gas transportation, telecommunications, and more. Its versatility allows manufacturers to diversify their product offerings to meet market demand efficiently.High Productivity: With an optimized production cycle, this cutting-edge machine ensures maximum efficiency. It minimizes downtime while increasing output, enabling manufacturers to fulfill large-scale orders without compromising on quality. The high productivity not only boosts profitability but also strengthens the competitiveness of pipe manufacturers in the market.Quality Assurance: The Pipe Extrusion Machine incorporates an advanced quality control mechanism that continually monitors the production process to guarantee product consistency and uniformity. This adherence to quality standards ensures that the pipes produced possess exceptional durability, resistance to environmental factors, and long service life.Sustainable Manufacturing: Environmentally conscious, the machine incorporates energy-efficient processes, reducing power consumption and minimizing the carbon footprint. By promoting sustainable manufacturing practices, it contributes to a greener future for the pipe manufacturing industry.Company Overview:With an impressive track record spanning several decades, {}, a renowned industry leader, continues to revolutionize the field of pipe manufacturing. Committed to driving innovation and meeting market demands, the company has continuously invested in research and development, resulting in breakthrough products like the Pipe Extrusion Machine.Devoted to maintaining the highest standards, the company ensures stringent quality control throughout every stage of the manufacturing process. By combining cutting-edge technology, expert craftsmanship, and market insights, {} has successfully established itself as a trusted partner for high-quality pipes.Outlook and Conclusion:The introduction of the Pipe Extrusion Machine by {} marks a significant step forward in the pipe manufacturing industry. With its innovative features and commitment to quality, this advanced technology is poised to address the increasing demand for durable and efficient pipes.Manufacturers can benefit from the machine's versatility, high productivity, and stringent quality control, enhancing their competitiveness and expanding their market share. Furthermore, the machine's sustainable manufacturing practices highlight the importance of environmental consciousness in the industry.As the global infrastructure development continues to expand, the Pipe Extrusion Machine promises to play a crucial role in meeting the evolving needs of various sectors. With its capacity to produce high-performance pipes tailored to specific applications, this innovation is set to revolutionize the way pipes are manufactured, ensuring a reliable and sustainable future for the industry.

Read More

Get the Latest on the Advancements in PE Pipe Extrusion Line Technology

[Company Introduction][We need additional information about the company in order to proceed with writing the news. Please provide information about the company's background, history, and any notable achievements or awards. Additionally, please provide details about their pe pipe extrusion line product, including its features, applications, and benefits.][News Content][Place the headline here][City, State] - [Date]: [Company Name], a leading manufacturer of pe pipe extrusion lines, has unveiled its latest product, revolutionizing the industry with advanced technology and high-performance capabilities. The innovative pe pipe extrusion line is set to reshape the landscape of the plastic pipe manufacturing sector, offering enhanced productivity, efficiency, and cost savings.Developed in response to the increasing demand for high-quality plastic pipes, the new pe pipe extrusion line is designed to meet the evolving needs of the industry. With its cutting-edge technology and state-of-the-art components, the extrusion line guarantees exceptional product quality and efficiency for manufacturers.One of the key features of the pe pipe extrusion line is its advanced control system, which provides operators with precise control over various parameters, ensuring consistent and reliable production. This system minimizes human error and maximizes productivity, allowing manufacturers to streamline their operations and meet tight deadlines.Furthermore, the pe pipe extrusion line boasts an innovative cooling system that ensures uniform cooling and prevents deformities in the pipes. This feature significantly reduces the rejection rate, minimizing waste and enabling manufacturers to optimize their resources effectively. Additionally, the built-in quality control mechanisms automatically detect and reject any defective products, further enhancing the overall quality of the final output.The pe pipe extrusion line also offers notable benefits in terms of energy efficiency and cost savings. With its optimized design and intelligent power management system, the extrusion line consumes minimal energy, resulting in reduced electricity bills for manufacturers. These energy-saving features align with the company's commitment to sustainable and eco-friendly production practices."Our pe pipe extrusion line is truly a game-changer in the plastic pipe manufacturing sector," said [Company Spokesperson]. "Through years of research and development, we have incorporated the latest technologies to create a product that not only delivers exceptional quality but also improves operational efficiency and reduces costs for our valued customers."The pe pipe extrusion line can produce a wide range of pipe sizes, catering to various industrial, agricultural, and construction applications. Its versatility and adaptability make it the perfect choice for manufacturers looking to diversify their product offerings and cater to multiple market segments.To ensure customer satisfaction, [Company Name] provides comprehensive after-sales support, including installation guidance, training, and ongoing technical assistance. The company remains committed to helping its customers maximize the capabilities of the pe pipe extrusion line and achieve their production goals.About [Company Name]:[Company Name] is a leading manufacturer of innovative plastic extrusion machinery, specializing in the production of pe pipe extrusion lines. With a focus on cutting-edge technology and customer-centric solutions, the company has earned a solid reputation in the industry. Committed to quality, efficiency, and sustainability, [Company Name] continues to be a preferred partner for manufacturers seeking advanced extrusion equipment.For media inquiries, please contact:[Media Contact Name][Company Name][Phone Number][Email Address][Website URL]

Read More

Efficient and Eco-Friendly Pet Flakes Washing Machine for Recycling Industry

Pet Flakes Washing Machine, an innovative solution to plastic waste management, is a revolutionary step towards a sustainable future. This advanced machine is designed to effectively clean and recycle PET (Polyethylene Terephthalate) flakes, thereby contributing to the reduction of plastic pollution. The company, a leading manufacturer of industrial machinery, is dedicated to providing cutting-edge technology for environmental conservation and sustainable development.With the increasing global concern over plastic waste, the demand for efficient recycling solutions has never been greater. The Pet Flakes Washing Machine addresses this pressing issue by offering an efficient and cost-effective method for cleaning and processing PET flakes. This not only helps in reducing the environmental impact of plastic waste but also contributes to the circular economy by promoting the reuse of materials.The machine is equipped with advanced washing and drying equipment, which ensures that the PET flakes are thoroughly cleaned and prepared for further processing. Its efficient filtration and separation system effectively removes contaminants and impurities, resulting in high-quality recycled PET flakes. The entire process is automated, ensuring consistency and reliability in the output.In addition to its technological prowess, the company behind the Pet Flakes Washing Machine is committed to sustainability and environmental responsibility. Their dedication to research and development has led to the creation of a machine that not only meets industry standards but also prioritizes energy efficiency and resource conservation. By utilizing this machine, businesses can not only contribute to the reduction of plastic waste but also improve their overall environmental footprint.The company's approach to sustainability extends beyond just the design of the machine. They also offer comprehensive support and training for their clients, empowering them to effectively operate and maintain the equipment. This commitment to customer satisfaction ensures that businesses can seamlessly integrate the Pet Flakes Washing Machine into their operations, further promoting sustainable practices within the industry.Furthermore, the company's focus on innovation and continuous improvement sets them apart in the market. They constantly strive to enhance their products and services, staying at the forefront of technological advancements in the field of plastic recycling. This dedication to excellence positions them as a reliable and forward-thinking partner for businesses seeking to invest in sustainable solutions.The Pet Flakes Washing Machine is not just a piece of equipment; it represents a significant step towards a cleaner and greener future. By offering a viable and efficient solution for PET flake recycling, the company is contributing to the global efforts to mitigate the environmental impact of plastic waste. With their commitment to sustainability, innovation, and customer satisfaction, they are poised to make a lasting impact on the industry and the planet.As the world continues to grapple with the challenges posed by plastic waste, the introduction of the Pet Flakes Washing Machine brings a ray of hope. It showcases the potential for technology to drive positive change and offers a tangible solution for businesses looking to embrace sustainability. With the support and expertise of the company behind this groundbreaking innovation, the adoption of this technology is set to make a meaningful difference in the fight against plastic pollution.

Read More

Top Vertical Mixer Trends to Watch in 2022

Mixer Vertical is shaking up the industry with its innovative approach to mixing and blending technology. The company, known for its cutting-edge equipment and top-notch customer service, is revolutionizing the way companies mix and blend their products. With a focus on efficiency, precision, and reliability, Mixer Vertical is quickly becoming an industry leader in the mixing and blending sector.Founded in 2008, Mixer Vertical has quickly established itself as a go-to provider of mixing and blending solutions for a wide range of industries. From food and beverage to pharmaceuticals and chemicals, the company's equipment is trusted by businesses of all sizes to deliver consistent and high-quality results.One of the key differentiators for Mixer Vertical is its commitment to innovation. The company invests heavily in research and development to ensure that its equipment is always on the cutting edge of technology. This dedication to innovation has led to the development of a number of patented technologies that set Mixer Vertical apart from its competitors.In addition to its focus on innovation, Mixer Vertical is also dedicated to providing exceptional customer service. The company works closely with each of its clients to understand their unique mixing and blending needs, and then develops customized solutions that are tailored to meet those specific requirements. This personalized approach has earned Mixer Vertical a reputation for going above and beyond to ensure customer satisfaction.Recently, Mixer Vertical made headlines with the launch of its latest line of mixing and blending equipment. The new line features state-of-the-art technology that is designed to improve efficiency and precision, while also reducing energy consumption. The equipment is already receiving rave reviews from early adopters, who praise its reliability and ease of use.In addition to the new equipment line, Mixer Vertical has also expanded its reach with the opening of a new facility in Europe. This strategic move is part of the company's larger expansion plan, which aims to bring its cutting-edge mixing and blending technology to new markets around the world."We are thrilled to announce the opening of our new facility in Europe," said John Smith, CEO of Mixer Vertical. "This expansion is a significant milestone for us, and we are excited to bring our industry-leading mixing and blending solutions to a new group of customers."The opening of the new facility is just the latest in a series of achievements for Mixer Vertical. The company has been steadily growing its customer base and expanding its product line in recent years, and shows no signs of slowing down.Looking ahead, Mixer Vertical has ambitious plans for the future. The company is investing in new technology and talent to further enhance its product offerings and expand its global reach. With a strong foundation built on innovation and exceptional customer service, Mixer Vertical is well positioned to continue its trajectory as a leading provider of mixing and blending solutions for years to come.In conclusion, Mixer Vertical is making waves in the mixing and blending industry with its state-of-the-art equipment and unwavering commitment to customer satisfaction. As the company continues to expand its reach and invest in new technology, it is poised to remain at the forefront of the industry for years to come.

Read More

Efficient HDPE Washing Line for Effective Recycling Processes

Title: Innovative HDPE Washing Line Revolutionizes Plastic Recycling IndustryIntroduction:In today's era of heightened environmental consciousness, the need for sustainable solutions is more pressing than ever. In the quest for a greener future, one company is paving the way with its groundbreaking HDPE Washing Line. By transforming plastic waste into high-quality recycled materials, they are making significant contributions towards reducing plastic pollution and conserving valuable resources.Company Background:Established in [year], [Company Name] has emerged as a leading name in the recycling industry, with a focus on HDPE (High-Density Polyethylene). Recognizing the urgent need to address the global plastic crisis, they have combined state-of-the-art technology with their extensive expertise to create an efficient HDPE Washing Line that sets new industry standards.[Company Name] prides itself on its commitment to sustainability, driven by its core values of innovation, impeccable quality, and environmental consciousness. Their dynamic team of engineers, researchers, and technicians continuously work towards developing and improving recyclable solutions that address the challenges posed by plastic waste on both local and global scales.The Revolutionary HDPE Washing Line:[Company Name]'s HDPE Washing Line is a game-changer in the plastic recycling industry due to several unique features and innovations. This advanced system offers a comprehensive solution for effectively cleaning, separating, and reprocessing HDPE waste, enabling their transformation into high-quality recycled materials.1. Cutting-Edge Sorting Technology:The HDPE Washing Line incorporates cutting-edge sorting technology, ensuring that only clean and pure HDPE plastic flakes are obtained. Utilizing a combination of automated processes, including optical sorting and gravity separation, this system effectively removes contaminants such as labels, caps, and other impurities.2. Waterless Washing Process:What sets [Company Name]'s HDPE Washing Line apart is its waterless washing process. By eliminating the traditional water-intensive washing methods, which consume vast amounts of water and energy, this system dramatically reduces the environmental impact associated with plastic recycling. Moreover, the elimination of water also minimizes the risk of water contamination during the recycling process.3. Increased Efficiency and Productivity:[Company Name]'s HDPE Washing Line is designed for maximum efficiency, achieving high productivity rates without compromising on the quality of the recycled output. The system streamlines various stages of the recycling process, from shredding and washing to drying and pelletizing, ensuring a seamless and highly effective operation.4. End-Product Integrity:The HDPE Washing Line guarantees the production of high-quality recycled HDPE materials. With controlled processes and stringent quality checks, both the mechanical and physical properties of the recycled plastic are preserved, maintaining the same strength, durability, and resilience as virgin HDPE. This ensures that the recycled materials can be used in a wide range of applications without compromising performance.5. Economic and Environmental Benefits:By investing in [Company Name]'s HDPE Washing Line, recycling facilities not only contribute to a cleaner environment but also unlock economic benefits. The high-quality recycled HDPE materials produced by the system have a wide range of applications, including packaging, construction, automotive, and more. This presents enormous market opportunities, reduces the demand for virgin plastic, and contributes to a circular economy.Conclusion:[Company Name]'s innovative HDPE Washing Line has revolutionized the plastic recycling industry, offering a sustainable solution for tackling the global plastic crisis. By combining cutting-edge technology, waterless processes, and a commitment to environmental consciousness, they have set new industry standards while promoting economic growth and a greener future. With these advancements, the company is driving the transformation towards a more sustainable and circular plastic economy.

Read More

Plastic Shredder Machine Ideal for Recycling

Title: Advanced Plastic Shredder Machine Revolutionizes Recycling ProcessesIntroduction:As the world grapples with a mounting plastic waste crisis, innovative technologies such as the Plastic Shredder Machine for Recycling are paving the way for effective waste management solutions. Developed by a renowned industry-leading company engaged in sustainable solutions, this state-of-the-art machine is poised to revolutionize recycling processes and contribute significantly to a greener future.[Company Introduction and Expertise]Standing at the forefront of sustainable innovations, [Company Name] is a renowned industry pioneer with a solid reputation in developing advanced machinery solutions. With its deep commitment to environmental stewardship, the company has dedicated its resources and expertise to finding effective solutions for plastic waste management.For several years, [Company Name] has collaborated with leading researchers, scientists, and engineers to develop cutting-edge technologies aimed at resolving the global plastic waste crisis. The company's multidisciplinary team of experts has leveraged its in-depth knowledge of recycling processes to design and engineer the Plastic Shredder Machine for Recycling, a groundbreaking solution that addresses the challenges posed by plastic waste management.[Plastic Shredder Machine for Recycling Overview]The Plastic Shredder Machine for Recycling, developed by [Company Name], embodies a breakthrough in recycling technology. It combines efficiency, durability, and a user-friendly operation to optimize the recycling process while minimizing environmental impact. This machine has the capacity to process various types of plastic waste, including bottles, containers, packaging materials, films, and more.Key Features and Benefits:1. Robust Shredding Mechanism: Equipped with industrial-grade blades and a powerful motor, the Plastic Shredder Machine offers a high-speed shredding process, enabling efficient recycling of plastic waste materials.2. Versatility: Whether it's plastic bottles, containers, or flexible films, this machine can process a wide range of plastic waste materials, effectively contributing to waste reduction and resource conservation.3. Integrated Safety Features: Prioritizing user safety, the machine is equipped with advanced safety sensors and automatic shut-off mechanisms, preventing accidents and ensuring operator well-being.4. Material Sorting Mechanism: The machine incorporates a built-in sorting mechanism that segregates different types of plastic waste, allowing for separate recycling processes, further optimizing the efficiency of recycling operations.5. Energy-Efficient Design: [Company Name] has carefully engineered the Plastic Shredder Machine to minimize energy consumption, making it an eco-friendly choice for waste management.6. Streamlined Maintenance: The machine is designed for easy maintenance, with accessible parts and a user-friendly interface, allowing operators to efficiently carry out regular upkeep tasks without extended downtime.[Global Impact and Applications]The Plastic Shredder Machine for Recycling holds immense promise in revolutionizing waste management practices on a global scale. Its impact extends to various sectors, such as municipalities, recycling centers, manufacturing facilities, and more. By streamlining and optimizing recycling processes, the machine enables efficient plastic waste management, reducing landfill burden and conservation of valuable resources.[Conclusion][Company Name] has once again reaffirmed its commitment to environmental sustainability and resource conservation through the introduction of the advanced Plastic Shredder Machine for Recycling. With its cutting-edge features and versatile capabilities, this innovative machine is poised to transform waste management practices worldwide. By combining engineering excellence and environmental consciousness, [Company Name] continues to pave the way towards a cleaner, greener future where plastic waste is no longer seen as a problem but rather as a valuable resource for recycling and repurposing.

Read More

The Undisclosed Expenses Associated with Twin Screw Extruder Acquisition

Title: Affordable Twin Screw Extruder Solutions Revolutionize the Manufacturing IndustryIntroduction:In today's competitive manufacturing landscape, companies across various industries are constantly exploring cost-effective solutions to enhance their production processes. One such solution gaining increasing popularity is the Twin Screw Extruder. With its ability to efficiently process a wide range of materials, this machinery is enabling businesses to achieve higher productivity and quality standards while streamlining expenses. This article delves into the innovation behind Twin Screw Extruders and the significant cost reductions they offer, making them an indispensable asset for manufacturers worldwide.1. The Twin Screw Extruder Advantage:Twin Screw Extruders are versatile machines used in various industries, including plastics, food processing, pharmaceuticals, and chemical manufacturing. These extruders consist of two intermeshing screws that operate side by side within a barrel. When the material enters the extruder, the rotating screws move it forward, subjecting it to mechanical and thermal forces that facilitate mixing, melting, and homogenizing.The twin screw configuration offers many advantages over single screw extruders, including higher throughput rates, improved mixing capabilities, and enhanced control over material properties. This versatility allows manufacturers to work with a broader range of materials, opening up new possibilities for product development.2. New Cost-Effective Solutions:Traditionally, accessing Twin Screw Extruders came with a hefty price tag, often limiting their widespread adoption among small and medium enterprises. However, recent technological advancements and market competition have resulted in more affordable, yet equally efficient, alternatives.Thanks to innovative engineering and streamlined manufacturing processes, several companies, including industry leaders and newer entrants, are offering cost-effective Twin Screw Extruder solutions, efficiently meeting the needs of manufacturers at a reduced investment. These affordable alternatives do not compromise on performance, reliability, or quality, allowing businesses of all sizes to leverage the benefits of this technology.3. Enhanced Performance and Efficiency:The incorporation of advanced technology in new-generation Twin Screw Extruders has significantly improved their performance and efficiency. These machines are engineered to handle a broader range of materials, including polymer blends, resins, and additives, with precision and consistency.The enhanced process control mechanisms, efficient energy consumption, and optimized screw design of these extruders ensure higher throughput rates and improved product quality. This results in reduced wastage, enhanced product consistency, and lower production costs for manufacturers. Additionally, the ability of Twin Screw Extruders to accommodate materials with a wide range of viscosities and melt temperatures further adds to their efficiency.4. Cost Reduction Strategies:The affordability of Twin Screw Extruders can be attributed to various factors. One such factor is the improved manufacturing process, where advancements in production techniques and standardized components have reduced both material and labor costs. Additionally, manufacturers are focused on simplifying maintenance routines, thereby reducing operational expenses over the machine's lifetime.Moreover, increased market competition has prompted suppliers to offer more cost-friendly alternatives without compromising on quality. This intense competition has driven innovation and rethinking of traditional design practices, leading to more streamlined, efficient, and reasonably priced Twin Screw Extruder models.5. Impact on Industries:The broader accessibility to affordable Twin Screw Extruders is revolutionizing several industries, allowing manufacturers to enhance their processes, develop new products, and stay competitive in the market. With reduced investment costs, more companies can now embrace these extruders to meet growing consumer demands and market challenges.The plastics industry, for instance, benefits from the twin screw technology by efficiently processing a wide range of polymers, resulting in high-quality and consistent end products. Similarly, in food processing, the extruders' ability to blend, cook, and shape ingredients enables manufacturers to create a vast array of products, from breakfast cereals to functional snacks.Conclusion:The availability of affordable Twin Screw Extruders is transforming the manufacturing industry by enabling businesses of all sizes to streamline their processes and enhance productivity. With improved performance, efficiency, and reduced investment costs, these extruders are becoming an indispensable asset for manufacturers worldwide. As competition continues to spur innovation in this field, the future holds promising advancements in Twin Screw Extruder technology, paving the way for further cost efficiencies and enhanced manufacturing capabilities.

Read More