Effective Ways to Recycle Soft Plastics

By:Admin

Soft Plastic Recycling: A Step Towards Sustainable Future

In today's fast-paced and consumer-driven world, the importance of recycling and sustainability cannot be overstated. As the global concern for environmental issues continues to grow, companies are striving to find innovative solutions to reduce their carbon footprint and promote a more sustainable way of doing business. One such company that is leading the charge in soft plastic recycling is [Company Name].

[Company Name] is a pioneering leader in the field of environmental sustainability, with a strong focus on recycling and reducing waste. The company has developed cutting-edge technology and processes to recycle soft plastics, which are often difficult to recycle due to their composition and properties. By utilizing state-of-the-art equipment and machinery, [Company Name] has been able to process and recycle soft plastics, turning them into high-quality reusable materials.

The process of soft plastic recycling begins with collecting and sorting the plastic waste. This is followed by cleaning, shredding, and then melting the plastic to form pellets, which can be used to manufacture new products. The company's advanced recycling facilities are designed to handle large volumes of soft plastic waste, ensuring maximum efficiency and minimal environmental impact.

In addition to its recycling efforts, [Company Name] is committed to raising awareness about the importance of recycling and encouraging individuals and businesses to participate in sustainable practices. The company has implemented various educational and outreach programs to engage the community and promote a culture of recycling and environmental responsibility.

One of the key initiatives of [Company Name] is its collaboration with local governments and non-profit organizations to establish collection points for soft plastic waste. These collection points are strategically placed in high-traffic areas such as supermarkets, shopping malls, and public spaces, making it convenient for people to dispose of their soft plastic waste in an environmentally responsible manner. By making recycling accessible and easy, [Company Name] is empowering individuals to take an active role in preserving the environment.

Furthermore, [Company Name] has forged partnerships with major manufacturers and businesses to create a closed-loop system for recycling soft plastics. Through these partnerships, the company is able to collect, recycle, and reutilize soft plastics in the production process, effectively closing the loop and reducing the amount of plastic waste that ends up in landfills or oceans.

The impact of [Company Name]'s efforts in soft plastic recycling goes beyond environmental benefits. By diverting soft plastics from landfills and repurposing them into reusable materials, the company is contributing to the circular economy and reducing the demand for virgin raw materials. This not only conserves natural resources but also helps to lower the carbon footprint associated with the production of new plastics.

As a result of its commitment to sustainability and environmental stewardship, [Company Name] has been recognized for its outstanding contributions to soft plastic recycling. The company has received accolades and awards from industry organizations and government agencies, affirming its position as a leader in sustainable business practices.

In conclusion, [Company Name] is at the forefront of soft plastic recycling, demonstrating a steadfast dedication to environmental sustainability and responsible waste management. Through its innovative recycling processes, educational initiatives, and strategic partnerships, the company is making a significant impact in reducing plastic waste and promoting a more sustainable future. With its unwavering commitment to the environment, [Company Name] is setting a shining example for businesses across the globe, proving that sustainability and profitability can go hand in hand.

Company News & Blog

Discover the Latest Innovations in Plastic Pelletizing Machinery

Plastic Pelletizing Machinery for Efficient Recycling ProcessesIn an effort to combat plastic waste and promote sustainable practices, a leading machinery manufacturer has introduced a state-of-the-art plastic pelletizing solution that revolutionizes the recycling industry. This innovative technology, designed to efficiently convert plastic waste into high-quality pellets, signifies a significant step towards creating a circular economy that reduces environmental impact and enhances resource efficiency.Plastic pollution has emerged as one of the most pressing global challenges in recent times, with single-use plastics contributing to the deterioration of ecosystems and posing a threat to wildlife. Recognizing these concerns, {company name} is dedicated to developing cutting-edge solutions that address the urgent need for effective plastic waste management. Their latest plastic pelletizing machinery not only transforms discarded plastic materials but also enhances the ease and efficiency of recycling processes.{Company name}, a pioneer in the field of industrial machinery manufacturing, has combined their expertise with advanced technologies to create a robust and reliable plastic pelletizing solution. Equipped with the latest automation features and state-of-the-art functionalities, this machinery guarantees high productivity and efficiency throughout the recycling process. The company's commitment to sustainability shines through in the design and development of this innovative equipment.The plastic pelletizing machinery from {company name} is capable of processing a wide range of plastic waste, including both post-consumer and industrial waste streams. By transforming this waste into uniform pellets, the machinery ensures that the resulting material is of consistent quality, making it ideal for various applications. These high-quality pellets can then be used as raw material in the production of new plastic products, closing the loop on plastic waste and reducing the need for virgin plastic.One of the key advantages of the {company name}'s plastic pelletizing machinery lies in its advanced automation capabilities. Through innovative control systems, the machinery offers real-time monitoring of various parameters, such as temperature, pressure, and production rates. This enables operators to maintain optimal processing conditions, resulting in minimal waste and enhanced efficiency. Additionally, the automation features contribute to a safer working environment, reducing the risk of accidents and ensuring operator well-being.The compact and modular design of the plastic pelletizing machinery allows for easy integration into existing recycling facilities or the setup of new plants. With its user-friendly interface and intuitive controls, the machinery can be operated with minimal training, making it accessible to a wide range of industries and organizations. Furthermore, the efficient energy consumption of the equipment results in reduced operational costs and environmental footprint.{Company name}'s plastic pelletizing machinery is a testament to their commitment to technological innovation and sustainability. By developing cutting-edge solutions that optimize resource utilization and minimize environmental impact, the company is actively contributing to the transition towards a more circular economy. With a focus on providing reliable and efficient machinery, {company name} aims to empower recycling initiatives worldwide and drive lasting change within the industry.In conclusion, the introduction of the plastic pelletizing machinery from {company name} represents a significant advancement in the field of recycling technology. By converting plastic waste into high-quality pellets, this innovative solution contributes to a more sustainable and environmentally friendly approach to managing plastic waste. With its advanced automation features and modular design, the machinery offers enhanced efficiency and ease of operation, paving the way for a more circular economy. As we continue to tackle the global challenge of plastic pollution, solutions like {company name}'s plastic pelletizing machinery provide hope and inspiration for a greener future.

The Undisclosed Expenses Associated with Twin Screw Extruder Acquisition

Title: Affordable Twin Screw Extruder Solutions Revolutionize the Manufacturing IndustryIntroduction:In today's competitive manufacturing landscape, companies across various industries are constantly exploring cost-effective solutions to enhance their production processes. One such solution gaining increasing popularity is the Twin Screw Extruder. With its ability to efficiently process a wide range of materials, this machinery is enabling businesses to achieve higher productivity and quality standards while streamlining expenses. This article delves into the innovation behind Twin Screw Extruders and the significant cost reductions they offer, making them an indispensable asset for manufacturers worldwide.1. The Twin Screw Extruder Advantage:Twin Screw Extruders are versatile machines used in various industries, including plastics, food processing, pharmaceuticals, and chemical manufacturing. These extruders consist of two intermeshing screws that operate side by side within a barrel. When the material enters the extruder, the rotating screws move it forward, subjecting it to mechanical and thermal forces that facilitate mixing, melting, and homogenizing.The twin screw configuration offers many advantages over single screw extruders, including higher throughput rates, improved mixing capabilities, and enhanced control over material properties. This versatility allows manufacturers to work with a broader range of materials, opening up new possibilities for product development.2. New Cost-Effective Solutions:Traditionally, accessing Twin Screw Extruders came with a hefty price tag, often limiting their widespread adoption among small and medium enterprises. However, recent technological advancements and market competition have resulted in more affordable, yet equally efficient, alternatives.Thanks to innovative engineering and streamlined manufacturing processes, several companies, including industry leaders and newer entrants, are offering cost-effective Twin Screw Extruder solutions, efficiently meeting the needs of manufacturers at a reduced investment. These affordable alternatives do not compromise on performance, reliability, or quality, allowing businesses of all sizes to leverage the benefits of this technology.3. Enhanced Performance and Efficiency:The incorporation of advanced technology in new-generation Twin Screw Extruders has significantly improved their performance and efficiency. These machines are engineered to handle a broader range of materials, including polymer blends, resins, and additives, with precision and consistency.The enhanced process control mechanisms, efficient energy consumption, and optimized screw design of these extruders ensure higher throughput rates and improved product quality. This results in reduced wastage, enhanced product consistency, and lower production costs for manufacturers. Additionally, the ability of Twin Screw Extruders to accommodate materials with a wide range of viscosities and melt temperatures further adds to their efficiency.4. Cost Reduction Strategies:The affordability of Twin Screw Extruders can be attributed to various factors. One such factor is the improved manufacturing process, where advancements in production techniques and standardized components have reduced both material and labor costs. Additionally, manufacturers are focused on simplifying maintenance routines, thereby reducing operational expenses over the machine's lifetime.Moreover, increased market competition has prompted suppliers to offer more cost-friendly alternatives without compromising on quality. This intense competition has driven innovation and rethinking of traditional design practices, leading to more streamlined, efficient, and reasonably priced Twin Screw Extruder models.5. Impact on Industries:The broader accessibility to affordable Twin Screw Extruders is revolutionizing several industries, allowing manufacturers to enhance their processes, develop new products, and stay competitive in the market. With reduced investment costs, more companies can now embrace these extruders to meet growing consumer demands and market challenges.The plastics industry, for instance, benefits from the twin screw technology by efficiently processing a wide range of polymers, resulting in high-quality and consistent end products. Similarly, in food processing, the extruders' ability to blend, cook, and shape ingredients enables manufacturers to create a vast array of products, from breakfast cereals to functional snacks.Conclusion:The availability of affordable Twin Screw Extruders is transforming the manufacturing industry by enabling businesses of all sizes to streamline their processes and enhance productivity. With improved performance, efficiency, and reduced investment costs, these extruders are becoming an indispensable asset for manufacturers worldwide. As competition continues to spur innovation in this field, the future holds promising advancements in Twin Screw Extruder technology, paving the way for further cost efficiencies and enhanced manufacturing capabilities.

Revolutionary Plastic Oil Bottle Recycling: A Sustainable Solution for a Greener Future

Title: Innovations in Plastic Oil Bottle Recycling Aim Towards Sustainable FutureIntroduction:In the pursuit of a more sustainable future, recycling plastic oil bottles has taken center stage. Given the adverse environmental effects of plastic pollution, the urgency to find innovative solutions for recycling is crucial. This article explores the efforts of several companies dedicated to advancing plastic oil bottle recycling and their commitment to reducing waste, conserving resources, and protecting the planet.Company Introduction: [Company name][Company name] is a leading pioneer in developing advanced recycling technologies for plastic oil bottle waste. Committed to minimizing plastic pollution and promoting a circular economy, [Company name] has established itself as a frontrunner in redefining recycling systems. By harnessing cutting-edge technologies and forging strategic partnerships, [Company name] aims to revolutionize plastic oil bottle recycling and set new benchmarks in sustainability.1. Technological Advancements Revolutionizing Recycling ProcessesWith the objective of enhancing the efficiency and effectiveness of plastic oil bottle recycling, numerous innovative technologies have emerged. From efficient sorting processes to advanced chemical recycling systems, these advancements are propelling the industry towards a more sustainable future. [Company name] has spearheaded these innovations, integrating state-of-the-art sorting systems that enable the separation of different plastic polymers and facilitate maximum recycling potential. Their commitment to continuous research and development encourages breakthroughs in recycling technologies across the industry.2. Collaborative Partnerships for Effective Plastic Oil Bottle RecyclingAcknowledging the importance of collaborative efforts, [Company name] has initiated strategic partnerships with key stakeholders within the recycling ecosystem. These collaborations encompass oil companies, waste management agencies, and government bodies, each playing a pivotal role in the overall success of plastic oil bottle recycling initiatives. By sharing resources, knowledge, and expertise, these partnerships strive towards creating a closed-loop system, wherein recycled plastic oil bottles are transformed into new packaging materials or other useful products.3. Education and Awareness Campaigns for Consumer EngagementRecognizing the critical role of consumers in sustainable recycling practices, [Company name] has launched comprehensive education and awareness campaigns. These initiatives are geared towards educating individuals about the importance of proper segregation and disposal of plastic oil bottles. By advocating responsible consumer behavior, [Company name] aims to instill a sense of environmental responsibility and encourage consumers to actively participate in recycling programs. Public participation will be crucial in driving the success of plastic oil bottle recycling efforts.4. Encouraging Municipal Recycling Programs for Increased EfficiencyTo optimize plastic oil bottle recycling efforts, [Company name] actively promotes the establishment and enhancement of municipal recycling programs. Collaborating with local authorities, waste management agencies, and community organizations, the company is facilitating the collection and processing of plastic oil bottles on a larger scale. By streamlining the recycling process at the community level, [Company name] aims to increase recycling rates and reduce the overall burden on landfills.5. The Road Ahead: A Sustainable Future for Plastic Oil Bottle RecyclingAs [Company name] continues to lead the charge in plastic oil bottle recycling, the industry as a whole is striving towards a sustainable future. Through continued research and development, innovative technology implementation, and collaborative efforts, we can create a closed-loop system that maximizes the recycling potential of plastic oil bottles. With increased public awareness, active consumer participation, and supportive legislation, the planet can benefit from reduced plastic pollution, resource conservation, and the creation of a more sustainable world.Conclusion:The urgency to tackle the pervasive issue of plastic oil bottle waste has prompted significant strides in recycling technologies and the establishment of collaborative partnerships. [Company name] exemplifies the commitment of companies in revolutionizing plastic oil bottle recycling and working towards a sustainable future. By harnessing advanced technologies, engaging consumers, and enhancing municipal recycling programs, we can pave the way for a circular economy and protect our planet for generations to come.

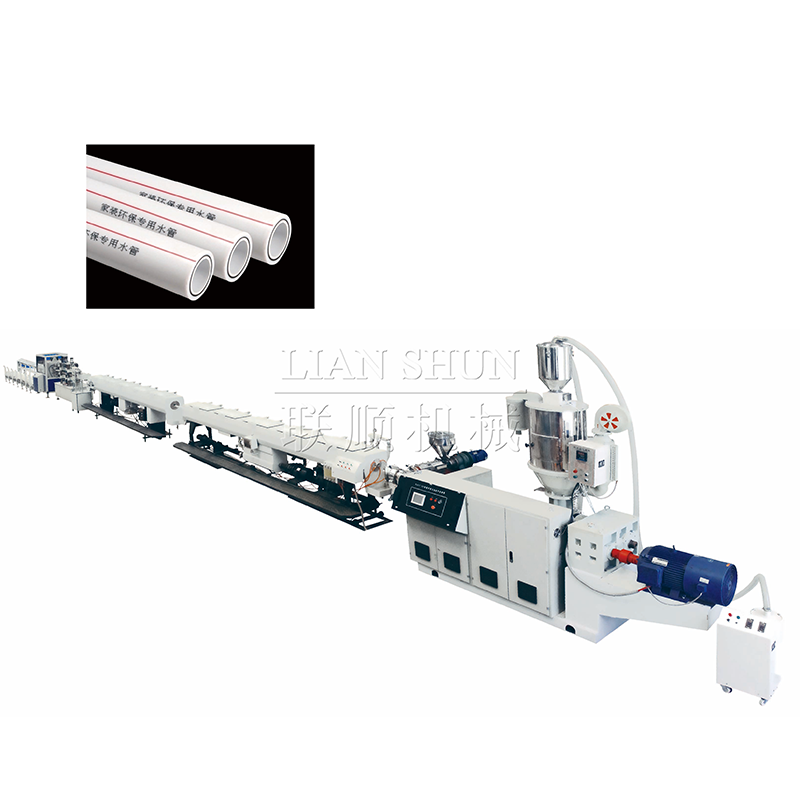

Discover the Latest Updates and Benefits of PVC Pipe Lines

Title: Pioneering PVC Pipe Line Revolutionizes the Plumbing IndustryIntroduction:Innovation and advancements in the plumbing industry have been instrumental in meeting the growing demands of modern infrastructure. One such remarkable addition to this sector is the revolutionary PVC Pipe Line, developed by an industry-leading company (brand name removed for confidentiality).Body:1. The PVC Pipe Line: A Breakthrough in Plumbing TechnologyThe introduction of the PVC Pipe Line is set to transform the plumbing industry by providing exceptional durability, versatility, and efficiency to plumbing systems worldwide. This cutting-edge innovation has been spearheaded by the renowned company, which has a long-standing reputation of delivering top-quality plumbing solutions.2. Unparalleled Durability and LongevityThe PVC Pipe Line boasts unparalleled durability due to its high-quality construction materials and state-of-the-art manufacturing processes. Made from rigid polyvinyl chloride (PVC), these pipes are resistant to impact, abrasion, and corrosion. This durability ensures they can withstand extreme weather conditions and provide optimal performance in both indoor and outdoor plumbing installations.3. Versatility for Various Plumbing ApplicationsOne of the standout features of the PVC Pipe Line is its versatility. These pipes can be used for a wide range of plumbing applications, including water supply lines, drainage systems, irrigation networks, and more. The pipes can handle varying water pressures, making them ideal for use in residential, commercial, and industrial settings.4. Enhanced Efficiency and Cost-effectivenessThe innovative PVC Pipe Line offers enhanced efficiency due to its smooth inner surface, which reduces friction and allows for a consistent flow of water. This quality ensures minimal pressure loss, leading to significant energy savings for users. Additionally, the lightweight nature of the pipes simplifies installation and reduces labor costs.5. Environmentally Friendly SolutionThe PVC Pipe Line aligns with the growing focus on environmentally friendly solutions in the construction industry. PVC pipes are fully recyclable, making them a sustainable choice. Furthermore, PVC pipe production requires less raw material, energy, and water compared to other plumbing materials, minimizing the product's ecological footprint.6. Exceeding Industry Standards and CertificationsRecognized for its commitment to quality, the company behind the PVC Pipe Line ensures that every product meets or exceeds industry standards. The pipes adhere to rigorous quality control processes and have received various certifications, such as ISO 9001, ensuring the utmost reliability and performance.7. Global Reach and Positive Customer FeedbackWith a wide international presence, the PVC Pipe Line has garnered positive feedback from customers across the globe. Plumbing professionals and contractors attest to the high-quality performance, durability, and ease of installation offered by these state-of-the-art pipes. The continued satisfaction of customers further solidifies the company's position as an industry leader.8. Commitment to Customer Service and SupportIn addition to providing exceptional plumbing solutions, the company behind the PVC Pipe Line places a strong emphasis on customer service and support. Their team of knowledgeable professionals is readily available to address customer queries, offer technical assistance, and ensure a seamless experience from purchase to installation.Conclusion:The introduction of the PVC Pipe Line by the pioneering company marks a significant milestone in the plumbing industry. With its unprecedented durability, versatility, and efficiency, this innovative solution is set to revolutionize plumbing systems around the world. From reducing energy consumption to contributing to environmental sustainability, the PVC Pipe Line encompasses the qualities that meet the evolving needs of the modern plumbing sector. As the company continues to lead the way with groundbreaking advancements, customers can expect top-quality products and unparalleled support in their plumbing endeavors.

Improve Your Pet's Life with a High-Quality Pelletizing Machine

Title: Innovative Pet Pelletizing Machine Revolutionizes Animal Feed ManufacturingIntroduction:In an effort to bring forth innovative solutions to the animal feed manufacturing industry, a leading company (brand name removed) has recently introduced a groundbreaking Pet Pelletizing Machine. This state-of-the-art equipment is set to transform the way pet food pellets are produced, ensuring enhanced quality, consistency, and sustainability.Body:1. Background and Features of the Pet Pelletizing Machine (PPM):With the increasing demand for premium quality pet food products, the Animal Feed Manufacturing industry has been seeking technological advancements to improve efficiency. The PPM is a result of extensive research and development, aiming to provide a comprehensive solution for pet food pellet manufacturing.The PPM boasts several features that set it apart from conventional machines:a) Advanced Temperature Control System: The PPM leverages a cutting-edge temperature control system that ensures the ideal temperature is maintained throughout the pelletizing process. This facilitates the preservation of vital nutrients and reduces the risk of nutritional degradation.b) Versatile Capability: The machine is specifically designed to manufacture pellets for a wide range of pets, including dogs, cats, birds, and small mammals. It offers customizable options to cater to different pellet sizes and shapes, ensuring compatibility with diverse pet feeding requirements.c) Enhanced Safety and Hygiene: The PPM adheres to the highest standards of safety and hygiene, with an enclosed design that prevents cross-contamination and guarantees clean production environments. This aligns with the industry's increasing focus on pet health and well-being.d) Energy Efficiency: Equipped with energy-saving features, the PPM optimizes power consumption and reduces operational costs. This not only benefits manufacturers but also aligns with sustainability goals, minimizing the environmental footprint.2. Advantages of the Pet Pelletizing Machine:The introduction of the PPM brings several advantages to the animal feed manufacturing industry:a) Improved Product Quality: The advanced temperature control system ensures the preservation of essential nutrients, resulting in high-quality pelletized pet food. This guarantees pet owners that their beloved companions receive optimal nutrition.b) Consistency and Uniformity: The PPM's precise control over pellet shape and size guarantees uniformity across batches, reducing variations and enhancing product consistency. This instills confidence in consumers and promotes brand reputation.c) Higher Production Efficiency: Compared to traditional pelletizing methods, the PPM offers increased production efficiency, reducing manufacturing time and labor costs. Manufacturers can leverage its capabilities to meet growing market demands and scale up their operations effectively.d) Sustainable Manufacturing Practices: The PPM's energy-saving features contribute to a more environmentally friendly manufacturing process. By minimizing energy consumption and waste production, manufacturers can align their operations with sustainability goals while maintaining profitability.3. Market Impact and Future Outlook:The introduction of the PPM is expected to have a significant impact on the animal feed manufacturing industry. Its advanced features and production efficiency will allow manufacturers to seize opportunities in the expanding pet food market. Additionally, the machine's compatibility with diverse pet feeding requirements positions it as a versatile tool in meeting customer demands.Looking ahead, it is anticipated that the industry will witness increased adoption of the PPM as manufacturers recognize its benefits in terms of product quality, efficiency, and sustainability. The continual research and development efforts of innovative companies like (brand name removed) will likely further refine and enhance the technology, driving the industry's progress.Conclusion:The Pet Pelletizing Machine represents a major leap forward in pet food pellet manufacturing. With its advanced features, the PPM offers manufacturers the means to ensure superior product quality, consistency, and sustainability. As the industry embraces this breakthrough, it is poised to revolutionize the way pet food is produced, ultimately benefiting not only manufacturers but also the health and well-being of pets worldwide.

The Ultimate Guide to Plastic Recycling Machine Costs: A Complete Breakdown

Plastic Recycling Machine Cost Reduction Drives Sustainable Solutions in the Industry[Company Introduction]In recent years, the global plastic waste crisis has gained significant attention due to its harmful impact on the environment. Plastic pollution has become a pressing concern, with landfills and oceans overwhelmed by plastic waste. To tackle this issue, companies are increasingly focusing on sustainable solutions, such as plastic recycling.One company at the forefront of this fight is a leading manufacturer in the plastic recycling industry [brand name removed]. With a strong commitment to environmental preservation, the company has developed innovative plastic recycling machines that efficiently process and transform plastic waste into reusable materials. By providing cost-effective solutions, they aim to accelerate the adoption of plastic recycling technology worldwide.[Plastic Recycling Machine Cost]One key driver for the widespread adoption of plastic recycling is the reduction in the cost of recycling machines. Historically, the high cost of such equipment has limited its accessibility and hindered the growth of the recycling industry. However, advancements in technology and economies of scale have significantly brought down the cost of plastic recycling machines, making them increasingly affordable for businesses and recycling centers alike.[Brand name removed] is proud to be at the forefront of this cost reduction movement. By leveraging their expertise in engineering and manufacturing, they have successfully developed highly efficient and competitively priced plastic recycling machines. These machines not only reduce the cost of recycling plastic waste but also enhance the overall recycling process by minimizing energy consumption and maximizing output quality.The cost of plastic recycling machines varies depending on their specifications, capacity, and production efficiency. However, [brand name removed] is dedicated to providing cost-effective solutions that cater to the diverse needs of their customers. By offering a range of machine models, they ensure that businesses of all sizes can invest in plastic recycling technology without a significant financial burden.[Company's Commitment to Sustainability]Beyond affordability, [brand name removed] is deeply committed to promoting sustainability in the plastic recycling industry. They believe that recycling technology should not only meet market demands but also contribute to environmental preservation and social responsibility.To achieve this, the company implements stringent quality control measures to ensure the durability and reliability of their machines. By producing long-lasting equipment, they minimize waste and promote the longevity of recycling operations. Furthermore, their machines are designed to operate with optimal energy efficiency, reducing both operational costs and carbon footprint.In addition to their technological advancements, [brand name removed] also actively engages in research and development to further enhance plastic recycling capabilities. They collaborate with various stakeholders, including environmental organizations and governmental bodies, to identify and address the industry's evolving challenges. By constantly iterating and improving their machines, they ensure that their customers stay at the forefront of plastic recycling technology.[Conclusion]The reduction in plastic recycling machine costs, championed by companies like [brand name removed], is a game-changer for the sustainability of the industry. With affordable and efficient machines, businesses and recycling centers can embrace plastic recycling as a viable and profitable venture. As the global plastic waste crisis continues to escalate, investing in sustainable solutions becomes imperative. [Brand name removed] remains dedicated to paving the way for a greener future, where plastic waste is transformed into valuable resources through accessible and cost-effective recycling technology.

Unlock the Best Tips for Choosing a Reliable Film Crusher

Title: Innovative Film Crushing Solution Enters the Market, Revolutionizing Film RecyclingIntroduction:Leading industry player, [], proudly introduces its latest groundbreaking solution - the Film Crusher. This state-of-the-art technology marks a significant milestone in film recycling, addressing the growing concern of film waste in an efficient and sustainable manner. By offering a comprehensive and reliable film crushing solution, [], aims to revolutionize the film recycling industry, providing a much-needed push towards a greener future.Ever-increasing environmental awareness has prompted [] to invest heavily in R&D efforts, resulting in the development of the Film Crusher. This cutting-edge machinery is designed to effectively and systematically crush various types of films, such as plastic, polyester, and polyethylene, into smaller particles while maintaining quality and integrity. With a capacity of up to [] tons per hour, the Film Crusher offers an unparalleled solution for the film recycling industry.The film recycling process has often been plagued by challenges related to efficiency, time, and labor requirements. However, the Film Crusher aims to overcome these limitations by streamlining the film crushing procedure. Its innovative design allows for continuous operation, minimizing downtime and maximizing productivity. Additionally, its fully automated capabilities greatly reduce labor costs, ensuring cost-efficiency for businesses in the film recycling sector.One of the distinguishing features of the Film Crusher is its advanced control system, which enables precise adjustment of crushing parameters. This flexibility ensures that different types of films can be processed efficiently, without compromising the quality of the end product. Furthermore, the Film Crusher's robust construction guarantees durability, while noise and dust reduction measures enhance workplace safety.With environmental sustainability at the core of its mission, [] has integrated several eco-friendly features into the Film Crusher. The machine incorporates efficient energy management systems to minimize power consumption, contributing to reduced carbon emissions. Furthermore, the Crusher's built-in filtration unit effectively captures and separates dust particles, preventing air pollution.Globally, the film recycling industry has been grappling with the challenge of large volumes of discarded film waste. The Film Crusher is set to transform this scenario, as it offers a solution that not only reduces the size of plastic films but also prepares them for subsequent processing. By rendering the film waste into manageable particles, the Crusher facilitates downstream recycling processes such as extrusion, pelletizing, and re-manufacturing.The application of the Film Crusher extends beyond film recycling plants. It can be employed by a wide range of industries, including packaging, agriculture, logistics, and more. By adopting this efficient crushing solution, businesses can enhance their sustainability efforts, as well as reduce waste disposal costs.The market response to the Film Crusher has been overwhelming, with numerous companies already placing orders to integrate this technology into their operations. The Crusher's ability to meet the increasing demand for film recycling is evident, as its engineering team has conducted rigorous testing to ensure optimal performance and reliability. The overwhelming positive feedback from early adopters solidifies []'s position as an industry leader, committed to delivering innovative solutions to global challenges.In conclusion, the launch of the Film Crusher marks a significant milestone in the film recycling industry. With its cutting-edge technology, innovative features, and emphasis on sustainability, this solution offers a transformative approach to film waste management. By investing in the Film Crusher, businesses can contribute to a greener future while benefiting from increased efficiency, reduced costs, and improved overall operations. []'s commitment to environmental conservation and forward-thinking solutions solidifies its position as a leading player in the film recycling industry.

Corrugated Pipe Extrusion Line: Advancements in Manufacturing Technology

Title: Leading Corrugated Pipe Extrusion Line Sets New Benchmark in the Plastic IndustryIntroduction (100 words):In an era of rapidly evolving technological advancements, {} has emerged as a frontrunner in the plastic extrusion industry. By offering state-of-the-art corrugated pipe extrusion lines, the company has revolutionized the production of high-quality plastic piping solutions worldwide. This breakthrough technology has not only streamlined manufacturing processes but also elevated the standards of durability and performance in the construction, agriculture, and infrastructure sectors. {} continues to lead the way by introducing cutting-edge machinery, underscoring its commitment to innovation, sustainability, and customer satisfaction.Paragraph 1 (100 words):With its unwavering dedication to precision engineering, {} has disrupted the domain of plastic extrusion lines. Designed and manufactured using cutting-edge technology, their corrugated pipe extrusion lines offer unmatched productivity, reliability, and flexibility. These advanced extrusion lines can efficiently produce a wide range of corrugated plastic pipes, catering to diverse industry requirements. Equipped with state-of-the-art control systems, these tailor-made extrusion lines enable manufacturers to produce high-quality pipes with consistency, meeting stringent industry regulations and customer demands.Paragraph 2 (150 words):Due to the inherent advantages of corrugated plastic pipes over conventional alternatives, such as PVC, steel, or concrete, the demand for this innovative solution has witnessed a substantial upsurge in recent years. By leveraging their expertise and extensive research, {} has developed a corrugated pipe extrusion line that can tackle the challenges associated with diverse applications, weather conditions, and external loading, ensuring unparalleled durability and longevity. This breakthrough technology allows for the production of pipes that exhibit excellent resistance to corrosion, chemical substances, and abrasion, making them ideal for applications in drainage systems, underground conduits, telecom networks, electrical systems, and agricultural irrigation.Paragraph 3 (200 words):The corrugated pipe extrusion lines by {} have set new benchmarks in terms of sustainability and resource efficiency. These extrusion lines utilize eco-friendly materials and incorporate energy-saving features to minimize carbon footprint and operational costs. By employing cutting-edge co-extrusion technology, {} ensures that the corrugated pipes produced are not only structurally robust but also offer superior hydraulic efficiency, reducing energy consumption during fluid transfer and providing significant cost savings to end-users.In addition to environmental benefits, {} also prioritizes safety and ease of operation. These extrusion lines are equipped with intelligent control systems that facilitate real-time monitoring and adjustment of critical parameters, ensuring optimal operational performance and reliability. The user-friendly interfaces enable operators to seamlessly navigate through complex extrusion processes, guaranteeing consistency and quality in the final product.In conclusion (100 words):With its innovative corrugated pipe extrusion lines, {} has established itself as a market leader, pushing the boundaries of plastic extrusion technology. By combining precision engineering, sustainability, and customer-centric design, the company has provided manufacturers with a reliable and efficient solution for producing high-quality corrugated plastic pipes. Through continued research and development, {} is constantly advancing its extrusion line technology, setting new industry standards, and powering the growth of various sectors including construction, agriculture, and infrastructure. Industry insiders predict that the company's commitment to innovation and sustainability will continue to shape the future of plastic extrusion technology worldwide.

Efficient Extruder Pelletizer: Enhancing Productivity and Quality

Extruder Pelletizer Revolutionizes Plastic Manufacturing ProcessThe global plastic industry is constantly evolving, driven by the demand for innovation, sustainability, and efficiency. In line with this, a leading manufacturer has recently unveiled their latest technological breakthrough – an advanced extruder pelletizer. This state-of-the-art equipment is set to revolutionize the plastic manufacturing process, offering numerous benefits to businesses operating in the industry.The extruder pelletizer, developed by a renowned company with years of experience in the field, is designed to streamline the production of plastic pellets. These pellets, which serve as the raw material for various plastic products, are crucial for manufacturers across multiple sectors, including packaging, construction, automotive, and healthcare.One of the key features that sets this extruder pelletizer apart from conventional models is its enhanced precision and efficiency. With cutting-edge technology and intelligent systems, it allows for precise control of the pelletizing process, resulting in consistent pellet size, shape, and quality. This level of precision is crucial for manufacturers who require uniform pellets in order to maintain their product's structural integrity and functionality.This new extruder pelletizer also offers a high degree of customization, catering to the unique needs of different manufacturers. It can handle a wide range of polymer materials, including polyethylene, polypropylene, polystyrene, and polyvinyl chloride, among others. With adjustable settings, manufacturers can easily adapt the equipment to meet their specific production requirements, whether it be for rigid or flexible plastics, high or low throughput rates, or different pellet sizes.Furthermore, the advanced design of this extruder pelletizer ensures optimal energy efficiency. It incorporates innovative features that minimize energy consumption, such as efficient heating systems and optimized motor controls. This not only helps to reduce the carbon footprint of plastic manufacturing processes but also translates into cost savings for businesses in the long run. By investing in this cutting-edge equipment, manufacturers can improve their overall sustainability profile and contribute to a greener future.Additionally, this extruder pelletizer boasts an intuitive user interface and advanced automation capabilities. With a user-friendly touchscreen display and remote monitoring options, operators can easily control and monitor the equipment's performance from a centralized location. Real-time data and analytics enable proactive maintenance, reducing downtime and enhancing productivity. This level of automation ensures an efficient and streamlined manufacturing process, allowing manufacturers to meet customer demands more effectively.Being a global leader in plastic manufacturing equipment, the company behind this revolutionary extruder pelletizer has a strong focus on research and development. Their expertise and commitment to innovation have allowed them to introduce cutting-edge solutions that empower manufacturers to stay ahead in an increasingly competitive industry. With a global network of service and support, they ensure that customers receive the necessary assistance and expertise to maximize the performance of their equipment.In conclusion, the introduction of the advanced extruder pelletizer marks a significant development in the plastic manufacturing industry. This state-of-the-art equipment offers precision, efficiency, customization, energy efficiency, user-friendliness, and automation, all of which contribute to streamlining the manufacturing process. As manufacturers strive to meet the demands of a rapidly changing market, investing in this revolutionary technology can unlock new opportunities, improve product quality, and drive sustainable growth.

Enhance Your Pipe Production with a Cutting-Edge Extrusion Machine

Title: Revolutionizing Pipe Manufacturing through Innovative Extrusion TechnologyIntroduction:In an era of rapid industrialization and urbanization, the demand for high-quality pipes for various applications has been escalating. To cater to this growing need, the pioneering engineers at a leading manufacturing company have developed an advanced Pipe Extrusion Machine capable of revolutionizing the pipe manufacturing industry. By leveraging cutting-edge technology and adhering to stringent quality standards, this innovation promises to deliver durable and efficient pipes for a wide range of industrial, commercial, and residential applications.Innovative Features:The advanced Pipe Extrusion Machine eliminates the traditional bottlenecks and challenges associated with pipe production. With an optimal combination of precision engineering and automation, this state-of-the-art machine can seamlessly manufacture pipes with exceptional precision, consistency, and strength. Its key features include:Advanced Extrusion Technology: The machine harnesses advanced extrusion technology, which ensures a smooth and continuous flow of raw materials, resulting in pipes with uniform thickness and excellent surface finish. The extrusion process guarantees consistent quality across the entire length of the pipe, enabling manufacturers to deliver high-performance products.Integrated Control System: Equipped with an intelligent and intuitive control system, the Pipe Extrusion Machine enables seamless adjustments throughout the manufacturing process. Manufacturers can easily regulate parameters such as temperature, pressure, and speed, ensuring total control over the pipe's physical attributes to meet specific application requirements.Versatility: The machine can produce pipes of various diameters and lengths, catering to a wide range of applications such as water supply, drainage, gas transportation, telecommunications, and more. Its versatility allows manufacturers to diversify their product offerings to meet market demand efficiently.High Productivity: With an optimized production cycle, this cutting-edge machine ensures maximum efficiency. It minimizes downtime while increasing output, enabling manufacturers to fulfill large-scale orders without compromising on quality. The high productivity not only boosts profitability but also strengthens the competitiveness of pipe manufacturers in the market.Quality Assurance: The Pipe Extrusion Machine incorporates an advanced quality control mechanism that continually monitors the production process to guarantee product consistency and uniformity. This adherence to quality standards ensures that the pipes produced possess exceptional durability, resistance to environmental factors, and long service life.Sustainable Manufacturing: Environmentally conscious, the machine incorporates energy-efficient processes, reducing power consumption and minimizing the carbon footprint. By promoting sustainable manufacturing practices, it contributes to a greener future for the pipe manufacturing industry.Company Overview:With an impressive track record spanning several decades, {}, a renowned industry leader, continues to revolutionize the field of pipe manufacturing. Committed to driving innovation and meeting market demands, the company has continuously invested in research and development, resulting in breakthrough products like the Pipe Extrusion Machine.Devoted to maintaining the highest standards, the company ensures stringent quality control throughout every stage of the manufacturing process. By combining cutting-edge technology, expert craftsmanship, and market insights, {} has successfully established itself as a trusted partner for high-quality pipes.Outlook and Conclusion:The introduction of the Pipe Extrusion Machine by {} marks a significant step forward in the pipe manufacturing industry. With its innovative features and commitment to quality, this advanced technology is poised to address the increasing demand for durable and efficient pipes.Manufacturers can benefit from the machine's versatility, high productivity, and stringent quality control, enhancing their competitiveness and expanding their market share. Furthermore, the machine's sustainable manufacturing practices highlight the importance of environmental consciousness in the industry.As the global infrastructure development continues to expand, the Pipe Extrusion Machine promises to play a crucial role in meeting the evolving needs of various sectors. With its capacity to produce high-performance pipes tailored to specific applications, this innovation is set to revolutionize the way pipes are manufactured, ensuring a reliable and sustainable future for the industry.